In theory, getting to space is simple — just go up, then keep going.

In reality, there are some additional steps: Collect a few billion dollars, build a rocket taller than a ten-story building, gain access to vast quantities of fuel and, preferably, buy a deserted plot of land that you wouldn't mind obliterating on launch day.

Or, you could do it like Brian Stofiel — just print a rocket in your basement and drag it to the edge of space on a weather balloon. Then, and only then, would you fire the rocket, which would have to be light enough to lift with a bit of helium but also sturdy enough to survive a prolonged burn through the upper atmosphere.

You probably wouldn't build that rocket out of plastic.

But Stofiel, a St. Louis-based Air Force veteran without a bachelor's degree, is doing just that, utilizing a heat-resident, chemically treated plastic that he himself invented. Stofiel's breakthrough has caught the attention of rocket scientists who know intimately what it takes to engineer an escape from Earth.

His creation, extruded inch by inch by an overworked 3D printer nicknamed "the Beast," is at the heart of what he calls the "Boreas" launch system.

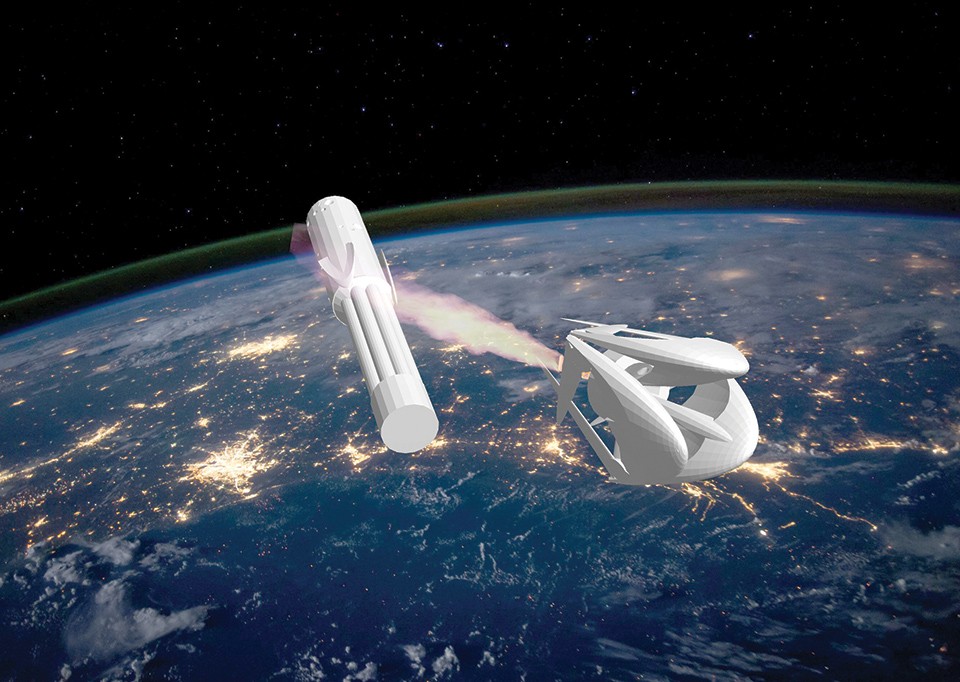

Without burning a drop of fuel, Boreas' launch would send an unguided balloon/rocket hybrid — a "rockoon" — bobbing and twisting into the sky. In Stofiel's plan, the balloon's single passenger would be a rocket named Hermes. Aside from its payload and fuel (and a bit of carbon fiber tube), Hermes would be made entirely of plastic.

Within an hour, Stofiel says, the balloon could rise to 90,000 feet, far above the domain of commercial aircraft.

Some 70 years ago, early rockets broke into orbit by using the technology behind ballistic missiles, their massive engines burning liquid oxygen and producing enough thrust to hit 17,000 miles per hour. But to a balloon, the sky simply opens its arms.

Beneath the rocket, tethered by yet another umbilical rope, would be a space plane with folded, swept-back wings. The size of a Mini Cooper, it looks like the fusion of a fighter jet and an origami crane. Called Artemis, it will hold Boreas' brain.

At nineteen miles up, the guidance computer would snap to work, writing a firing solution and sending the cue to Hermes to punch its ticket to space. When Hermes' engine ignites, its plastic motor would eject a pillar of flames at nearly 4,000 degrees Fahrenheit. With so little atmosphere remaining, Hermes would need only around two minutes of burn before it enters low-earth orbit, where it could then disgorge an army of imaging satellites.

Currently, Boreas is science fiction, a reflection of the still-unrealized ambitions of its creator and his company, Stofiel Aerospace. But the technology underpinning it is very real. Stofiel printed and fired dozens of small-scale Hermes prototypes from the backyard of his home in Boulevard Heights, and he's twice tested the rockoon design that would allow the rocket to bypass the thickest parts of the atmosphere.

He's still waiting to prove his central thesis: that in under a week, Stofiel Aerospace can custom-print a rocket, blast it into space and deliver an orbiting payload at an industry-low $20,000 per kilogram. That payload could be imaging satellites or scientific experiments. Eventually, Stofiel envisions Boreas becoming the preferred delivery service of the orbital economy, dropping packages on the other side of the world using a variation of the Artemis as a reentry vehicle.

It's a long overdue service for the commercial space age, Stofiel says, making his pitch above the noisy conversation of a monthly networking event at Cortex.

"You really need to be able to have that on-demand access to low-earth orbit," he adds. "I don't want to wait two years, or six months, I want to go to space next week. I just got tired of waiting on everybody else to do this."

With his biker-guy long hair, messy basement laboratory and intense antipathy for NASA, Stofiel often seems like a mad rocket scientist, both figuratively and literally. Stofiel Aerospace is also a family business, and Stofiel credits his daughter for inspiring Boreas in 2012, when she was five. (Now twelve years old and a veteran of NASA space camp, Stofiel's daughter is an official member of his company's board of directors.)

By any stretch, Stofiel Aerospace doesn't yet pose a challenge to SpaceX, the company founded by Elon Musk that now services more than half of all American commercial orbital space launches with a fleet of rockets that fire at $62 million a pop.

Rather, Stofiel has spent years taking the first small steps to turning his ideas into a viable space service. The modern space race remains dominated by governments, deep-pocketed entrepreneurs and massive aerospace corporations. But Stofiel's first steps have intrigued both rocket scientists and industry insiders.

Reaching into his briefcase, he produces a blackened rocket nozzle the diameter of a coffee mug. The surface is hard to the touch, the skin left bumpy and scarred by its encounter with rocket fuel.

"We call it positive structural molding," Stofiel says, describing the proprietary heat-shielded material in his hand. Turning the nozzle over, he points out the lack of structural distress, the strength of compartments designed to focus thousands of pounds of thrust.

It weighs almost nothing.

"And that's plastic from Microcenter at Brentwood," he adds, laughing. "That hit 2,000 degrees!"

In 1952, Earl Robb started his career designing airplanes at the McDonnell Aircraft Corporation, a St. Louis defense company with a history of manufacturing military fighters and missiles. By 1955, Robb was working on the problem of spaceflight. His work helped put the first American astronauts into space in 1961.

More than six decades later, on a morning in March 2018, Robb and three other retired McDonnell engineers descended into Brian Stofiel's basement.

Combined, they possessed about 300 years of expertise in rocket design and space engineering. They'd come to see for themselves if this 40-year-old entrepreneur was just boasting or, perhaps, truly brilliant.

They arrived in a basement workspace cluttered with 3D printers and rocket parts in various stages of construction and chemical treatment. Robb, 88, was used to operating with specialized teams toiling in the best facilities money could buy, and yet the scene was still a familiar one.

On a table, Stofiel had arranged dozens of rocket nozzles and components for the engineers' inspection. He also dragged out the reams of data he'd collected in the past five years of launches and static fire tests.

It made a believer of Robb.

"All my life, I dealt with heavy-duty structural things," Robb says now, recalling what he observed that morning. "He had this very light rocket. That just impressed the heck out of me. It still does."

Robb and Stofiel first met through monthly luncheons arranged by members of "Mac's Old Team," the name adopted by the retired McDonnell engineers whose work set the stage for NASA's Apollo missions to the moon. By putting astronauts in space for both the Mercury and Gemini projects, the McDonnell engineers left their mark on decades of space programs. Robb would later work on Skylab, the first manned U.S. space station, and his colleagues designed systems used in space-shuttle launches and the International Space Station.

Although NASA gets most of the credit for America's victories in the space race, early American programs were actually contracted to private industries, and McDonnell Aircraft was the major player of that era. The company's founder, James S. McDonnell Jr., would himself get on the intercom to make announcements to the Mercury and Gemini teams.

"This is Old Mac, Old Mac, calling all the team," Robb says, impersonating his old boss in a deadpan. The name stuck with the retirees, Robb explains, because it fits.

"We're all old now," he says, chuckling.

The group maintains a contact list with 200 or so names, and today's luncheon brings some twenty retirees to a private room in a Hibachi Grill in St. Charles. Stofiel, a regular attendee, is seated at a table against a wall, telling a former Gemini engineer about the impact of the government shutdown on planned rocket launches.

Robb steps into the middle of the room, welcomes the crowd and begins reading announcements. He informs the team of the passing one of its own, a former guidance and control-system designer for Mercury and Gemini spacecraft.

"Right now, it seems like we've got down to the point where there's not very many people passing away in our group," Robb remarks wryly. "The reason for that is... most of them have already gone." The room replies with a knowing groan of laughter.

But Robb and the members of Mac's Old Team are doing more than just ticking down the names of their still-living colleagues. For the last several years, the retired engineers have made the drive south to Bonne Terre, the rural Missouri town where their legacy is being preserved in a space museum.

And Robb and others see a commonality in Stofiel, a self-taught rocket scientist. At the start of the space program, every engineer had to be self taught.

"Just think of all the rockets that blew up in the late '50s and '60s trying to develop reliable launch vehicles," says Ron Jones, a Boeing engineer whose aerospace career began in the early 1970s – more than a decade after McDonnell Aircraft launched the first Mercury flight that proved rockets could indeed take men to space without exploding.

"It's just darn tough to build a rocket; it's probably the most difficult thing we can do, period," Jones adds. "Brian is going through the same process right now, and he's using a radical, contemporary approach to achieve it."

Stofiel's approach impressed Jones just as it did Robb, whose work on the Mercury program involved endless, painstaking efforts to shave ounces of metal from the heavy capsule.

But instead of designing a metal rocket for peak efficiency and lowest weight, as early space engineers did, Stofiel went one step further.

He got rid of metal entirely.